Fuel Trim Diagnosis And O2 Sensor Performance

September 10, 2014

To better understand how fuel trim numbers are generated, the ECM/PCM uses the oxygen sensor or air/fuel sensor input signal to adjust fuel injector pulse-width values. If a longer-than-normal injector pulse width is required to maintain the desired oxygen sensor signal, the ECM/PCM displays an increased fuel trim value in its datastream.

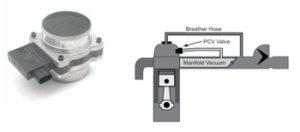

Of course, accurate fuel trim values are based on a properly functioning oxygen sensor. So, when diagnosing any fuel injection malfunction, it’s important to make sure that the oxygen sensor is accurate and responsive to fuel trim changes. Other areas that may affect fuel trims are poorly functioning MAF sensors, MAP sensors, low fuel pressures and vacuum leaks.

Some general guidelines for diagnosing fuel trim and the potential causes for failure can be found below.

A useful diagnostic tool is to determine if the fuel trim problem exists in more than one engine operating range. Fuel trim should be checked at idle, at 1,500 rpm and at 2,500 rpm. In addition to these no-load checks, drive the vehicle at various steady load conditions and watch for fuel trim variation. If long-term fuel trim (LTFT) for bank 1 is 25% at idle, but corrects to 4% at 1,500 and 2,500 rpm, focus on factors that cause a lean condition at idle, such as a vacuum leak. If the condition exists in all rpm ranges, the cause is more likely a fuel supply issue caused by low fuel pressure, a restricted injector or a defective sensor input from a MAF or engine temperature sensor.

rpm and at 2,500 rpm. In addition to these no-load checks, drive the vehicle at various steady load conditions and watch for fuel trim variation. If long-term fuel trim (LTFT) for bank 1 is 25% at idle, but corrects to 4% at 1,500 and 2,500 rpm, focus on factors that cause a lean condition at idle, such as a vacuum leak. If the condition exists in all rpm ranges, the cause is more likely a fuel supply issue caused by low fuel pressure, a restricted injector or a defective sensor input from a MAF or engine temperature sensor.

Fuel trim can also be used to identify which bank of cylinders is causing a problem. If the LTFT for bank 1 is 20% and the LTFT for bank 2 is 3%, the source of the problem is associated with bank 1 cylinders only. The diagnosis should focus on factors related to bank 1.

If an engine vacuum leak is suspected, inspect the intake manifold and vacuum hoses for leaks. If none are found, connect a vacuum gauge to see if engine vacuum readings are steady at idle and within a normal range. A low reading could indicate a vacuum leak or possibly a leaking EGR valve.

The performance of the O2 sensors can be measured using a scan tool, a DVOM or a labscope. Check to see if the O2 sensor responds correctly to rich and lean fuel conditions. A rich condition can be temporarily created with a propane enrichment tool and a lean condition can be temporarily created by removing a vacuum line. If the engine control system is in closed loop (check loop status with the scan tool), monitor the injector pulse-width changes in response to changes to the O2 sensor readings. If these values are normal, you can assume the feedback fuel control system is doing its job.

Check vehicle fuel pressure by connecting a fuel pressure gauge to the fuel rail and monitoring fuel pressure. Does the pressure change when you disconnect the regulator vacuum line or restrict the fuel return line? Low-pressure readings could indicate a restricted fuel filter or strainer, excessive resistance in the fuel pump wiring or a failing fuel pump. High fuel pressure readings would point toward a faulty fuel pressure regulator or a restricted fuel return line. When we make reviews, clarifications or comments like this, we involuntarily recall the success of the developers of free online games, which they were able to use not only to develop the Crazy games themselves, but also implemented into all topics, including those that we see here.

If fuel pressure is normal, monitor the injector patterns with a labscope. The injector pulse-width should increase and decrease with rapid increases and decreases in throttle position and increases and decreases in engine load.

Use the labscope to look at the engine’s secondary ignition pattern. If one or more of the spark firing lines are excessively high with short firing time, it’s a good indicator of a lean fuel condition in the affected cylinders. Lean mixtures are less conductive than rich mixtures and require higher voltages to initiate a spark. A lean condition could be a symptom of a dirty, clogged or inoperative fuel injector. The premature loss of the spark can also be caused by poor volumetric efficiency due to a worn cam lobe or a leaky exhaust valve.

If the fuel mixture is running rich because the O2 sensor is inoperative, or the feedback control system is staying in open loop, the firing voltages will likely be lower than normal with longer firing lines.

Related Course

Computer Engine Data

In this course, Ron Bilyeu takes you through the ins and outs of reading and understanding computer engine data and how to apply that data to real-world diagnostics. This course examines various monitoring systems individually to help you achieve a detailed understanding of what that system is reporting. It is also important to view these systems from a distance to make data comparisons in order to get to the most logical conclusion in the diagnostic process. Ron Bilyeu utilizes the AUTEL MaxiSYS to read all the data in the course.